Research

I view myself as both Artist and Technologist, with research and innovation a cornerstone of how I work to achieve my aesthetic and conceptual goals.

When I generate a concept of what I want to achieve I refuse to compromise until I know whether it is possible aesthetically and technically. Technology is a key tool to enable my aesthetic expression and I frequently work with industrial specialists innovating collaboratively to achieve my goals. Over my career I have often been told that something is not technically possible, but my fascination with where truth lies (see Outer Shell: Inner Space) has driven me to continually push the boundaries and explore whether this is actually the case.

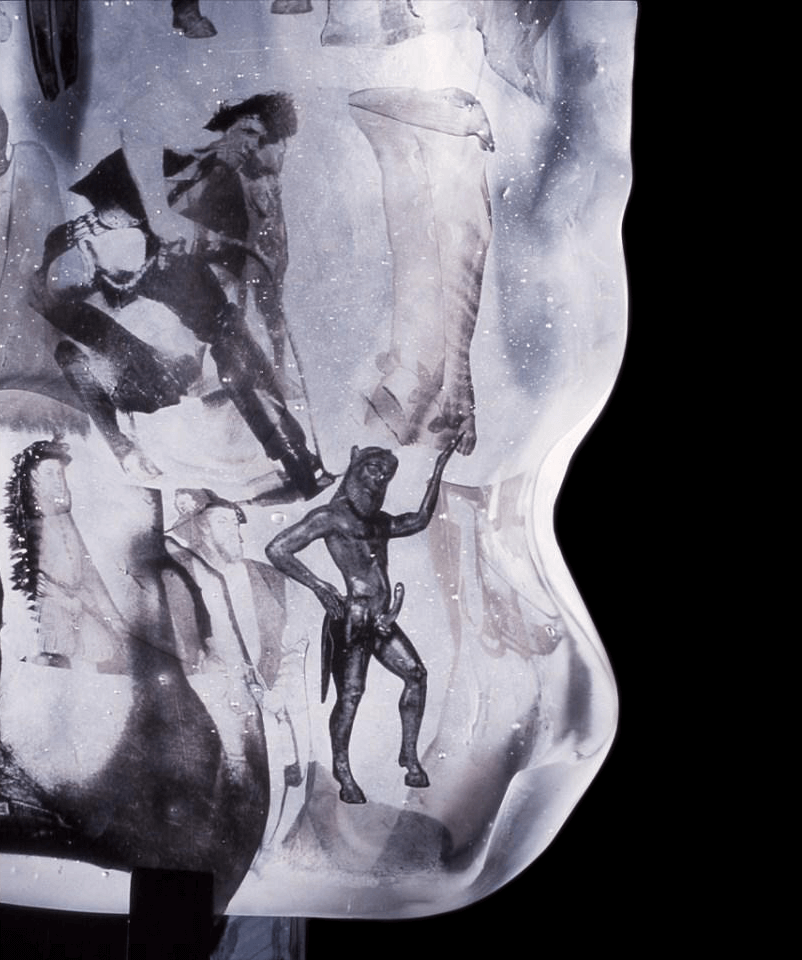

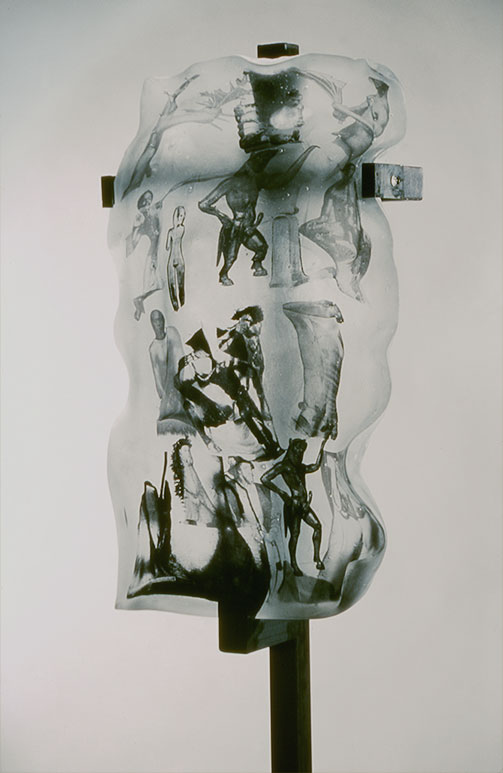

My technical research began with the challenge I faced in trying to express my conceptual investigation into where truth lies. To do this I wanted to be able to use a new space, not just the traditional shell that sculpture exhibits. By using glass, a transparent or semi-transparent medium, I was able to use both the outer shell and the inside space to explore this theme. I began to combine glass and to develop methods of using inclusions in innovative ways to express my concepts fully.

My initial technical research was concentrated, in general, on inclusions, such as prints, photographs, and holograms, and on controlling their shapes during the casting process. As a result of these studies, I developed a novel technique of image transfer onto glass. This technique was predominantly used on the surfaces of cast and blown glass, but I developed a new technique to apply images to multiple layers within the finished piece. Applying the printing directly to flat window glass and controlling the shape of the inclusions during the fusing of the layers of sheets was quite a straightforward process. However, incorporating images when slumping or casting into a mould presented a significant challenge, from applying the images onto the cast ingots to controlling the images as the ingots flow unevenly into the complicated mould forms.

Detail on this technique can be found in Kevin Petrie’s Glass and Print (ISBN-10: 0-7136-6491-6) and in my PhD thesis.

From here I moved into investigating metal inclusions within the creative (rather than industrial) sector. To achieve this, I explored techniques used in the industrial sector and how these can be applied in the creative sector. Different metals present different challenges due to their varying melting points, but I found that their inclusion was entirely possible and could create the results I was searching for to reflect my conceptual requirements.

Detail on these techniques can be found in my publications: Arts 2019, Arts 2021 journal and in my PhD thesis.

Gallium 99.9% , Nickel, Lead and Tin alloys inclusions in hot pouring glass into the moulds

As well as developing the scope of what is technically achievable with glass in the creative sector I have also worked with industry (Polish Cement Ltd) and academia (Academy of Technology, Kraków) in the development and use of semi-transparent concrete for fine art purposes.